Which material is better?Is Polyurethane Really Better than Plastic or Rubber? As with most material selection questions, the answer is“it depends”. Both materials have their place but which material is actually superior?

we devote our working lives to the manufacture of quality polyurethane products such as CPU bumpers. So you may wonder: what’s so great about polyurethane? The answer is in the versatility and many advantages over competing materials. If you’re curious as to why design engineers and production managers ought to make a point of considering polyurethane as the base for their parts and products

What is Polyurethane?

Polyurethanes (also called “urethanes”) are any of a family of elastomers, an artificial rubber. They are unique in combining the strength of rigid plastics with the flexibility and elasticity of rubber. Hoses, automotive bushings, seat foam, skateboard wheels, and Spandex are all common polyurethane applications.

Polyurethane is referred to as polyurethane. Polyurethane materials can be divided into three types according to their processing technology.

1, thermoplastic polyurethane elastomer (referred to as TPU)

2, pouring polyurethane elastomer (referred to as CPU)

3, mixing polyurethane elastomer (referred to as MPU)

Thermoplastic polyurethane elastomer (TPU) – Thermoplastic polyurethane elastomer accounts for about 25% of the total amount of polyurethane elastomer; Advantages can be thermoplastic molding, edge material can be recycled; the disadvantage is worse than the CPU strength, Hardness range is narrow, can not produce low hardness products.

Pouring type polyurethane elastomer (referred to as CPU) – polyurethane elastomer is the most widely used, the largest yield; the advantages of good temperature resistance, high strength. Wide range of hardness, can be very soft and extremely hard Disadvantages are not recyclable.

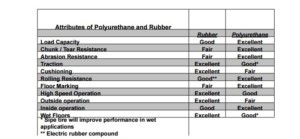

Advantages of Polyurethane: Substituting polyurethane components for rubber or plastic may offer the following advantages, just to name a few.

Durability. Polyurethane has exceptional abrasion and tear-resistance, typically better than rubber. It also has increasing load-bearing capacity, impact-resistance, and excellent wear properties.

Density Range. Polyurethane can be fabricated to be as soft as seat foam or hard as a table top!

Flexibility. Polyurethane’s outstanding elastic memory makes it a popular choice for furniture components.

Pliability. The combination of durability and pliability makes polyurethane the material of choice for medical supplies like feeding tubes or anatomical models.

In the case of tires, seals, and some belts, rubber is the best material In the case of tires, seals, and some belts, rubber is the best material. In the case of bushings, spacers, and high load components, polyurethane is the better choice..

Polyurethane has higher abrasion, cut, and tear resistance. It can be made in a higher hardness rating and it has better load bearing capacity. Polyurethane is easily colored, in some cases chemical resistant, and much easier and cost effective to mold into shapes and sizes.

Rubber by its soft nature allows for the absorption of vibrations and noise which may give the assumption that polyurethane isn’t as good for vibration dampening but polyurethane is also an excellent energy absorber and can be made in very low durometers.

In most cases polyurethane outperforms its rubber counterparts in replacement of many components including; bushings,and many others. The parts will last longer, standing up to chemicals and oils, and compression and load. Finally, polyurethane looks better than rubber.